Benefits

By implementing digital twins in your control software design and training simulators, you can revolutionize your approach to development and training. Enjoy unparalleled benefits such as improved quality, accelerated work processes, stress reduction, and significant cost savings. Transform your control software design and training methodologies to stay ahead in efficiency, safety, and overall effectiveness.

Benefits for control software design

Controllab has over 25 years of experience in the design, implementation and testing of control software for complex and advanced systems. The heart of these control systems are generally closed loop control systems. We use simulation models and all the classical (time domain, frequency domain, PID, Kalman filtering,…) and modern (adaptive control, machine learning,..) control techniques to make these control systems stable and efficient.

- Improve Quality: On a digital twin you can test all of your software long before the actual machine is available. Moreover you can test operations that are too expensive or too dangerous to test on the real machine. Longer and better testing will result in a huge quality improvement of your control software.

-

Work faster: On a digital twin you can instantly change the weather or any other condition and run any test that you want. With scripts you can run large sets of these tests automatically (test automation). And twins can be run in parallel. All in all you can work much faster with a digital twin than on a real machine.

- Reduce Stress: Working on a real machine, with tight deadlines and very high costs when something fails is very stressfull. A digital twin can simply be restarted when you make mistakes. This is a major stress reducer.

-

Save costs: If you have used a digital to develop your control system, the time for implementing the software on the real machine will reduce significantly. The real machine can be deployed much more quickly. If you work on software updates on an existing machine this means that the actual machine can continue running production while you are working on the digital twin in parallel.

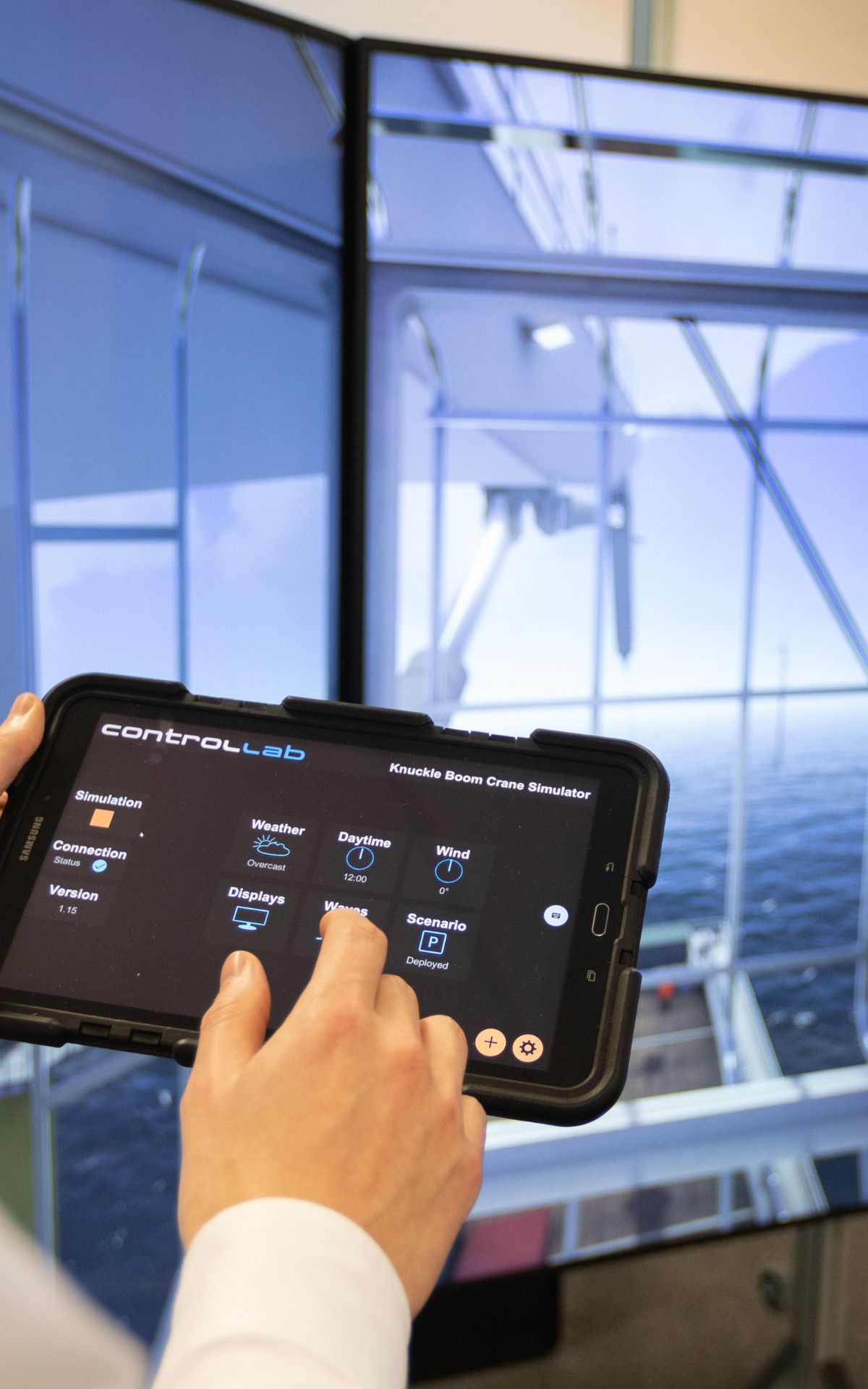

Benefits for training simulators

Training simulators are excellent for training operators to work with equipment in hazardous environments where the safety of people is at stake. With the advance of 3D imaging technologies and VR, the costs of the simulators are decreasing rapidly. They become a viable option in an increasing number of industries. Controllab provides training simulators for a number of industries.

- Improve Quality: On a digital twin you can run scenarios over and over again until the operator handles the machine perfectly. You can train operations that would be dangerous or harmful on a real machine a learn the operator to do the right actions when calamities happen. And you can include special training sessions that focus on the reduction of damage or the increase of performance.

-

Work faster: On a digital twin you can instantly change the weather or any other condition and run any training instantly. Working a day on a simulator is therefore equivalent to working several weeks on a real machine.Training on a simulator is therefor much faster than on a real machine.

- Reduce Stress: Working on a real machine with very high costs when something fails is very stressful, Especially if your a new on the job. On a digital twin, you can make mistakes without cost. This is a major stress reducer for operators.

-

Save costs: Training on a simulator will require much less assistance of trainers. Therefore you will directly save on educational cost. However, the biggest cost saver is found in the reduction of damage and a performance increase that is found with operators who are trained on a simulator.