Dredging

Controllab participates in a joint venture with MSA-Service. Under the name Dutch Dredging Simulators, we develop and release training simulators for the dredging industry.

Technology

The current simulators available on the market are expensive and voluminous. Dutch Dredging Simulators is focusing on simulators that are more transportable, cheaper and still realistically mimicking dredging operations. By using standard hardware, the costs are reduced. The software has been developed in-house. The result is a system that simulates all relevant aspects in detail. From start-up, to cutting the soil and pumping the sand-water mixture. The operator practices operations and learns how different conditions and settings influence the performance of the dredger.

Cutter section dredgers

The first simulator that has been released is a cutter suction dredging simulator. The simulator is based on a detailed physics model of the dredge which includes the hydraulic pumps, winches, anchor cables, spud poles and cutter head. This model is coupled to a ground model that contains the soil properties and allow dredging under various soil conditions.

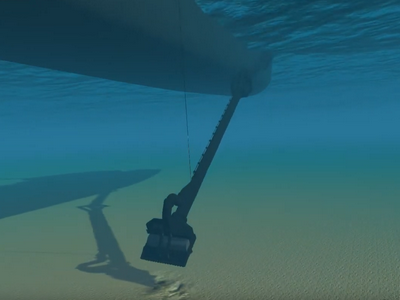

Trailing suction hopper dredger

We are currently working on a training simulator for a trailing suction hopper dredger. The simulator is based on a physics model that includes the ship motion in waves, a winch operated suction pipe and a detailed soil model. This training simulator will allow the operator to train the dredging operation under various conditions and learn how to maximize yield a while preventing overloading the dredge.

Digital Twins

On a digital twin you can test everything. Including the operations that are to expensive or to dangerous to test on a real machine. Better testing will bring better quality. Our trainingssimulators are just like real life, There is also the possibility to change the weather of any other condition.. The digital twin brings two worlds together. The training of the simalator will reduce the stress for the trainees. If you make a mistake, just restart the digital twin and start over. Not only the stress will be reduces but it also save costs.