Digital Twins

From Virtual reality to Real Innovation: Designing the Future with Digital Twins.

Offshore

High-Tech

Dredging

Steel

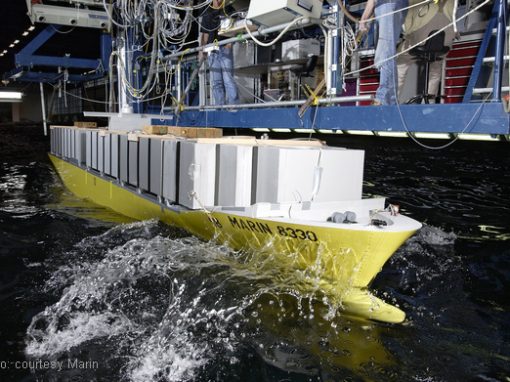

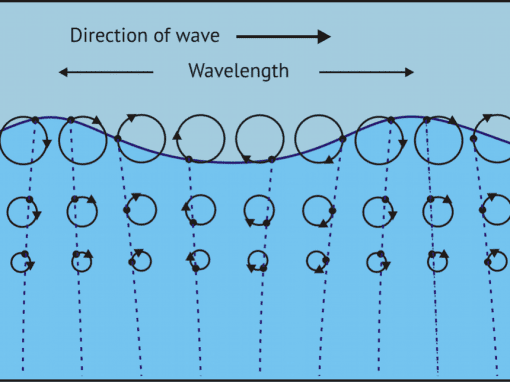

Modern machines are becoming more automated, digital, and intelligent. This poses a significant challenge when it comes to developing control software, especially for unique cases with limited testing and potential catastrophic failures. That’s where Controllab comes in. We specialize in digital twins, which are advanced simulation models that perfectly mimic real machines.

By applying physics principles and incorporating data from other machines, our simulation models behave just like the actual machines.

We excel at integrating these digital twins with control software, allowing them to operate in real-time as if you were controlling the physical machine. This makes our digital twins ideal for the development and testing of control software, also known as Hardware-in-the-Loop (HIL) simulation.

Controllab provide you with solutions for leveraging the power of digital twins in your control software development needs.

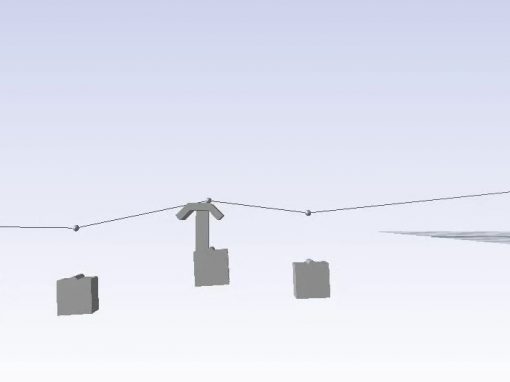

Design Studies

When you want to improve machines, there are limits in every part. Some of these limits are related to the maximum speed, some related to the mass, some related to the geometry and so on.

Training Simulators

Training simulators are excellent for training operators to work with equipment in hazardous environments where the safety of people is at stake.

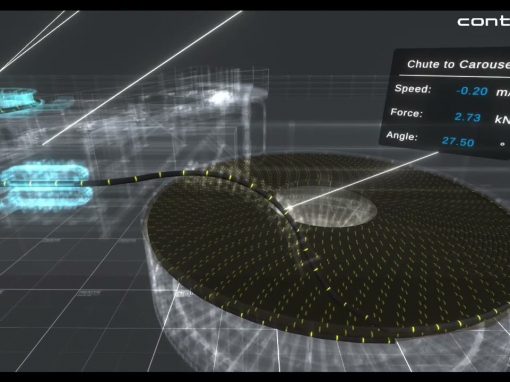

HIL Simulation

Our digital twins are simulation models that mimic real machines. We apply physics and use measurement data from other machines to make our simulation models behave exactly as the real machine.