What we use

Applications

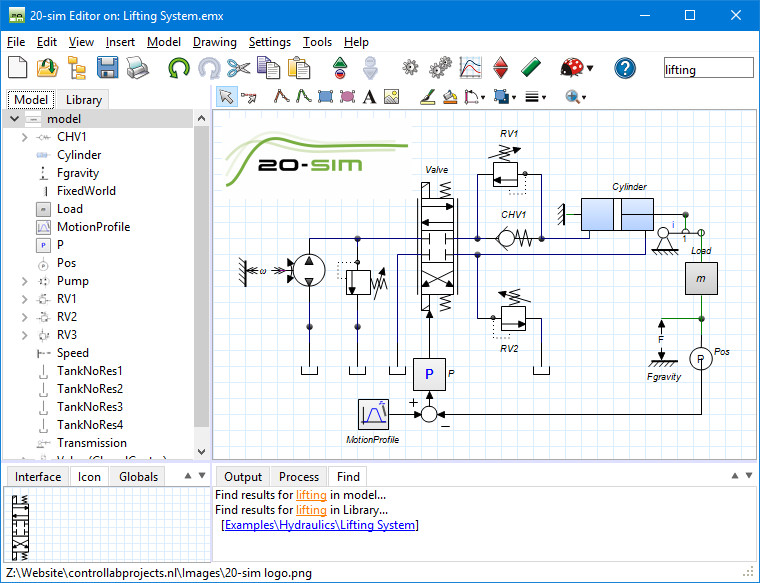

Application for Design studies

When you want to enhance machines, there are limitations in every aspect. Some of these limits are linked to the maximum speed, others to the mass, and others to the geometry, among other factors. At Controllab, our digital twins allow us to investigate these limits and analyze how they impact machine design. Through the creation of simulation models that incorporate these limitations, we are able to understand their effects on machine performance. Our simulations provide valuable insights for optimizing machine functionality.

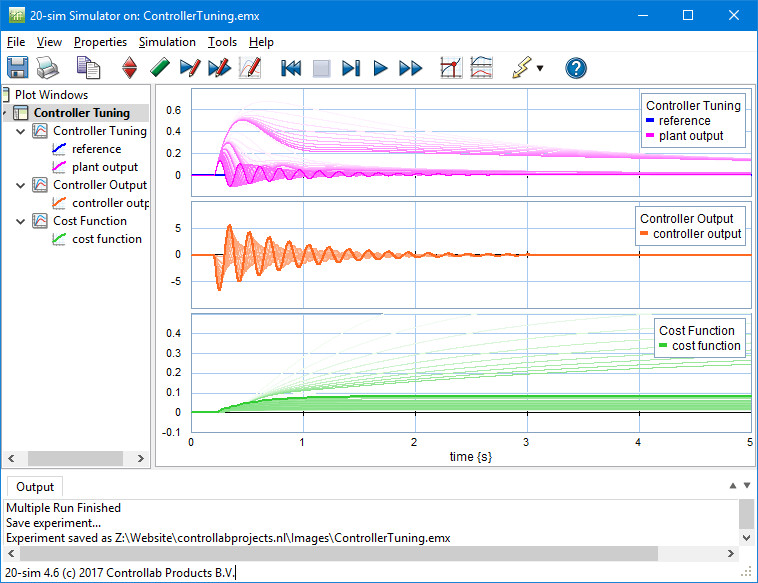

Control software design

Controllab has over 25 years of experience in the design, implementation and testing of control software for complex and advanced systems. The heart of these control systems are generally closed loop control systems. We use simulation models and all the classical (time domain, frequency domain, PID, Kalman filtering,…) and modern (adaptive control, machine learning,..) control techniques to make these control systems stable and efficient.

HIL Simulation

Our digital twins are simulation models that mimic real machines. We apply physics and use measurement data from other machines to make our simulation models behave exactly as the real machine. And we are experts in letting these models run in real-time. This allows us to couple our digital twins to external control software. This is called Hardware-in-the-Loop (HIL) simulation.

Training simulators

Training simulators are excellent for training operators to work with equipment in hazardous environments where the safety of people is at stake. With the advance of 3D imaging technologies and VR, the costs of the simulators are decreasing rapidly. They become a viable option in an increasing number of industries. Controllab provides training simulators for a number of industries.